Finned Heat Exchangers: Key Equipment for Efficient Heat Transfer

Finned heat exchangers are a common type of heat exchange equipment widely used in various industries and daily life applications, such as air conditioning, refrigeration, HVAC systems, and electronic equipment cooling. Their main function is to enhance heat transfer efficiency by increasing the heat exchange surface area, thereby enabling effective heat exchange. The design concept of finned heat exchangers is simple yet efficient, and their structure and working principle make them outstanding in terms of energy savings and heat exchange performance.

Basic Structure of Finned Heat Exchangers

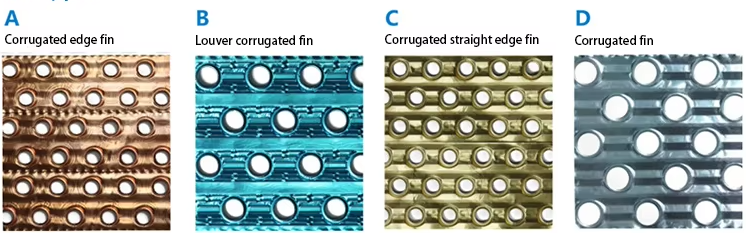

Finned heat exchangers typically consist of a base tube and fins. The base tube is the primary component through which heat is transferred by fluid, while the fins are metal plates attached to the exterior of the base tube. The primary function of the fins is to increase the heat exchange surface area, thereby improving heat transfer efficiency. Fins are usually made from metals with good thermal conductivity, such as aluminum, copper, and stainless steel. The shape of the fins can be flat, corrugated, or spiral, depending on the specific application requirements.

Working Principle

The working principle of a finned heat exchanger is based on the fundamental concept of heat transfer. When hot fluids (such as hot air, water, or steam) flow through the base tube, heat is transferred from the tube wall to the surrounding fins. Due to the large surface area of the fins, heat can be exchanged between the fins and a colder fluid (such as air or cooling water), causing the temperature of the hot fluid to decrease and the temperature of the cold fluid to rise. The design of the fins allows heat to be rapidly transferred from the fluid to the fin surface. By increasing the surface area of the fins, the heat dissipation process is accelerated, thereby improving the heat exchange efficiency.

Advantages of Finned Heat Exchangers

1.High Heat Exchange Efficiency

By increasing the heat exchange surface area, heat can be transferred more quickly, which results in higher heat exchange efficiency. This is especially beneficial in applications that require efficient heat dissipation, such as air conditioning systems and electronic device cooling, where finned heat exchangers provide stable and reliable heat exchange performance.

2.Space and Material Savings

The design of the fins significantly increases the heat exchange capacity per unit area, allowing finned heat exchangers to provide a large heat exchange surface in a relatively compact volume, saving both space and materials.

3.Strong Adaptability

Finned heat exchangers can be customized by adjusting the shape and arrangement of the fins to suit different fluid flow conditions and working environments. Whether in high-temperature, high-pressure environments or applications requiring high cooling capacity, finned heat exchangers can adapt flexibly.

Applications

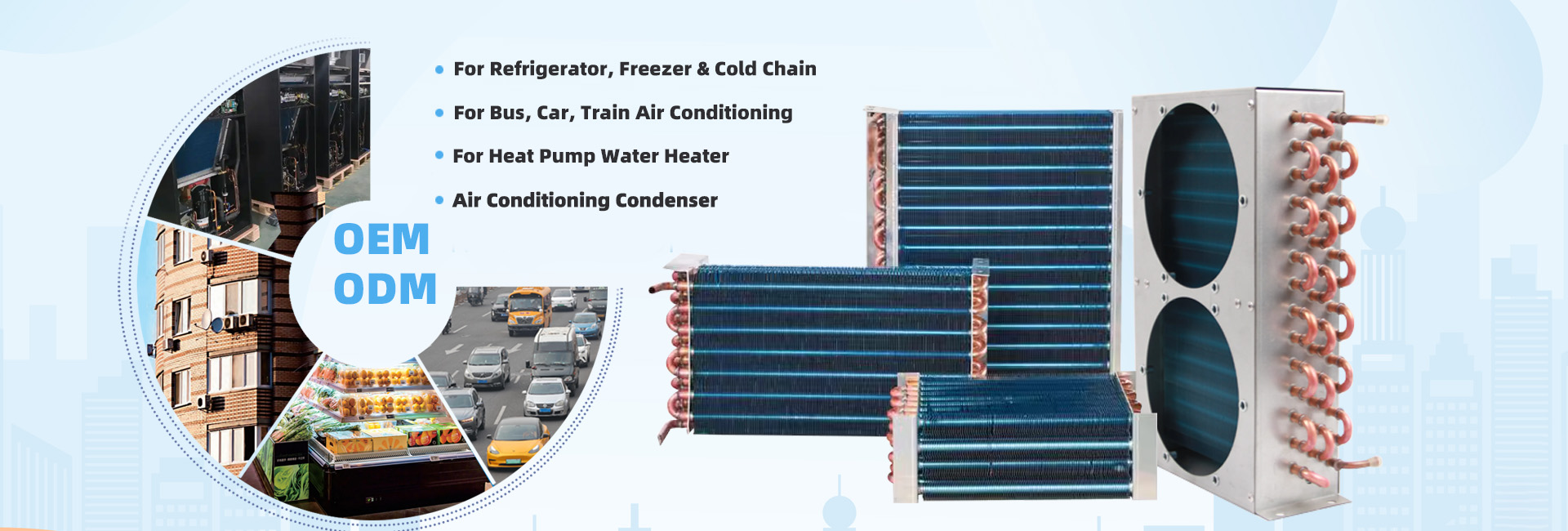

Finned heat exchangers are widely used in many industries. In the air conditioning and refrigeration industry, they are used as condensers and evaporators; in the automotive industry, they are employed for engine cooling; in the electronics field, they are used for thermal management solutions; and in chemical, petroleum, and natural gas industries, they are also commonly used in various heat exchange and cooling systems.

Conclusion

With their high heat exchange efficiency, compact structure, and wide range of applications, finned heat exchangers have become an indispensable part of modern industrial equipment. As technology continues to advance, the design and performance of finned heat exchangers are continually optimized, and they are expected to play an increasingly important role in more fields in the future.